Research and Development

Over 20 years of experience

Behind every Augen lens there are years of research, technology development of our own and new ophthalmic solutions. In order to achieve this, we are involved in the whole process which goes from lens design and the factory's equipment to the software that controls this equipment.

We know that good design is the beginning of clear, comfortable and natural vision. Augen's HD lenses are manufactured with our own free form technology. The result: precision without any error in the shape of a lens and a natural vision wherever you look.

WHAT WE DO

WHOLESALE

LABORATORIES

RESEARCH AND DEVELOPMENT

CHILDREN FRAMES

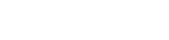

Free Form Technology

Free Form technology is a manufacture platform that allows for the production of asymmetric or Free Form surfaces.

Free Form generators are able to produce extremely complex surfaces with a high level of precision. In the past, these machines were extremely expensive and they depended on highly advanced optical systems. Nevertheless, the manufacturers of ophthalmic lenses and laboratories have begun to make the necessary investments to buy this kind of technology or even better, like in the case of Augen: to develop it.

Traditional generators that are used to cut the lenses need molds with specific curvatures for every prescription (Rx's) that is to say that for every visual deficiency of every patient there should be a specific mold. If we add that every series of molds is specific for every refractive index, what we obtain is that the traditional laboratories should have infinite series of molds for every material that they use, which does not happen for the cost would be very high. With the arrival of new Free Form technology, laboratories have the possibility of eliminating the mold system that is used for cutting lenses and obtain precise and personalized surfaces according to each patient's needs.

Nowadays, this type of technology is necessary because traditional generators and polishers used for cutting and polishing are not capable of cutting complex surfaces to meet the standards of the prescription and the precision required by the patients. Free form generators and polishers cut the lens surface through CNC systems (Computer Numerical Control) which results in perfectly controlled lens cutting.

Advantages of Free Form technology

- It eliminates the restrictions that laboratories have when manufacturing lenses with the precision and customization needed by each patient.

- Since these machines are controlled by computer, the margin of error and the lack of quality in the process are drastically reduced.

- It reaches the minimum center thickness possible according to the specifications for each material.

- Complex shapes can be cut (progressive, aspheric and double aspheric).

- It increases the range of materials that laboratories can offer because they will not depend on the mold for cutting.

Processing Equipment

A solution to all of your processing needs.

Maximum productivity through a simplified design.

EasyForm FF-V3

FREE FORM GENERATOR

Designed to facilitate Free Form production

- Unbeatable precision in the design with high quality surfaces based on NURB technology

- Quiet and efficient, ideal for every laboratory

- It processes surfaces in a free form or conventional way

- It is easy to load and unload, increasing general productivity

- Smooth and precise oscillatory movements in order to ensure curves of up to 1/100 diopters

- Robust diamond tools provide precision in curves that is greater than 20D without any need for changing the tools

- Lubricant recycling during the process in order to reduce waste and have a more hygienic environment in the laboratory

- Friendly interface with big buttons and clear instructions

- Easy-to-learn functions that avoid any need for hiring technicians

EasyForm FF-2LP

DIGITAL FREE FORM POLISHER

Operation 24/7 with a fast and precise polish

- Robust and resistant polisher with few mobile pieces

- Made to endure the severity of 24/7 operation

- Reduces the polishing time to half

- Precision in the tracking of progressive and in aspheric design curves to preserve the integrity of the lenses while deeply polishing

- Follows curves greater than 6D cyl and 20D surfaces without the need for changing tools

- Touch screen with big buttons and friendly interface that provides simultaneous views of each arm for maximum control and efficiency

- Includes parts and instructions to make your own polishing tools saving the typical expenses and reducing the time of order and the time you wait for replacements

EasyForm LFL2020

LASER ENGRAVING SYSTEM

Compact and cooled by air with precise engraving

- Advanced autofocus that provides greater lens engraving quality

- Engraves any type of thermosetting plastic, thermoplastic, metal, glass, wood and organic materials

- 17" Touch screen that allows maximum control in programming and commands

- Easy to see and understand, it has big buttons and clear instructions

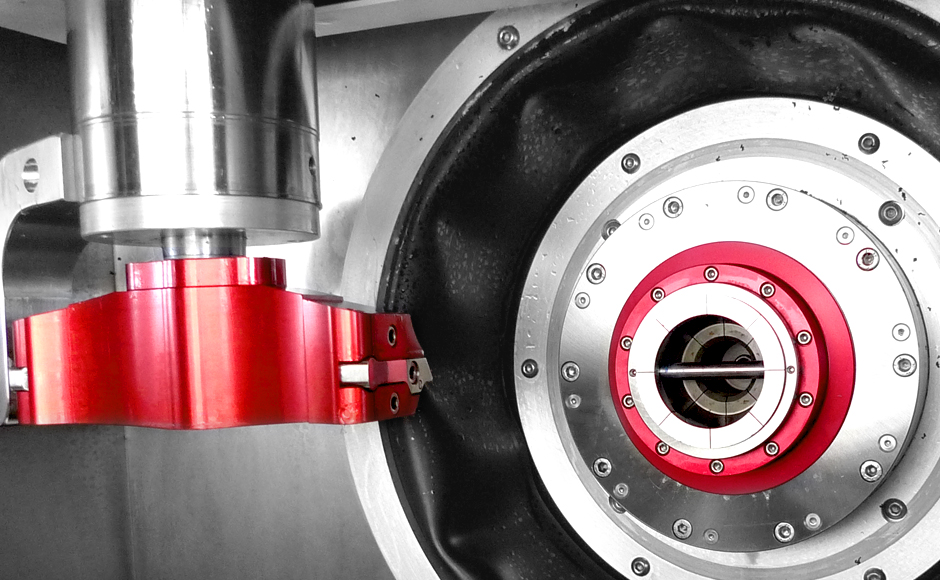

EasyForm FFSB

SPEED BLOCKER

It surpasses other double blockers and does not requires cooling

- Precise control of heating and machined blocks reduce the required amount of alloy, decreases the block assembly time, eliminates the need for cooling down and reduces time

- The alloy is maintained hot and liquid and never blocking the power supply

- Produces up to 160 lenses per hour in any power supply from flat to high curvatures

- Color block code improves easy selection

- Without deviation curve after blocking due to the machined block and to the minimum required alloy

Request more information on our Free Form equipment and

start your own independent laboratory