New type of production. Now instead of a factory, there may be products at lower cost, more specific and everything coming out of printers instead of big machines.

Imagine that you are in your office and your most important client requires your product with some specific changes immediately. Normally you would panic, stop production, call your engineers to make the necessary adjustments and would have the answer in at least a month ... Or could you do it immediately? The answer is yes.

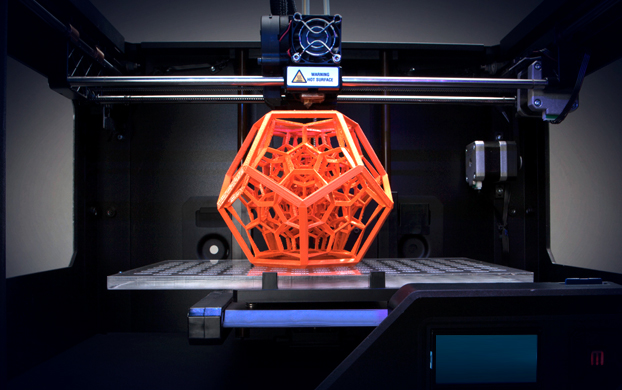

Thanks to the new technology called "Additive manufacturing", additive fabrication or 3D production, depending on the region where it is used, you can produce the product you need through a computer and a three-dimensional printer which, layer by layer, will generate the product in question.

The first industrial revolution was held in Britain in the late XVIII century with the mechanization of the textile industry, then in the early XX century came inline production thanks to Henry Ford, which led to mass production as we know it. But now, this new technological revolution will allow to make cheaper and fewer things, which will be more flexible in the development and use less labor.

Created by Chuck Hull in 1986, the three-dimensional printer works using a beam of ultraviolet light to solidify a thin layer of liquid plastic and some ink, repeating this process until the product is finished. So far, it has been used mainly to generate prototypes of various products such as cars, but experts say that in the near future, more than 80 percent of the things we use every day will be made this way, from a hammer to the wing of an airplane will be built in an office instead of a factory as is currently done.

In AUGEN OPTICOS, always ahead, three-dimensional printers are used to develop the design of the frames used in the program "Ver Bien", whose patented design, developed exclusively for AUGEN by Swiss designer Yves Behar, allowed making a frame especially for children, which is safe, ergonomic, lightweight and suitable to the tastes and needs of Mexican students.

Through Additive manufacturing technology, three-dimensional printing could be generated first and thus ensure that they fit most of the children and from these impressions, the parameters were adjusted for the final design.

Since the beginning of AUGEN OPTICOS' participation as a technology partner in the program "Ver Bien", they have delivered more than one million glasses, and expectations for the coming 2013-2014 school year are that half a million more will be needed.

Surely in the near future, you will have in your hands a pair of glasses whose frame will be generated by AUGEN OPTICOS specifically for your type of face and needs, printed in the optics of your choice immediately and through a three-dimensional printer.